Dakota CMX Corrosion Thickness Gauges

Product Description

Top of the range and easy to use, the Dakota CMX Corrosion Thickness Gauges provide inspectors with all the features necessary to measure the material and coating thickness at the same time.

User definable limits for pass/fail indication

Set limits for pass/fail indication on individual reading or for each batch with audible & visual warnings.

Store each measurement for further analysis

Up to 4GB of readings can be saved into the gauge memory as each measurement is taken, which can be downloaded later into an inspection application or into DakMaster™ Software for further analysis and reporting.

Able to measure coating and material thickness

The Dakota CMX Ultrasonic Thickness Gauges have the ability to measure coatings and material thickness simultaneously while maintaining the ability to locate pits, flaws and defects in the material.

Choose & customise the reading display

The Dakota CMX Thickness Gauge range has a choice of display modes allowing the user to select the most appropriate for their needs; Readings, B-Scan, B-Scan combined with readings, Scan bar & the A-Scan on the Dakota CMX2-DL Corrosion Thickness Gauge and Dakota CMX3-DL Corrosion Thickness Gauge.

Dakota CMX Corrosion Thickness Gauges

The Dakota CMX ultrasonic corrosion thickness gauge is available in four models – from an entry level Dakota CMX1 Ultrasonic Thickness Gauge to the top of the range Dakota CMX3-DL Ultrasonic Thickness Gauge.

- Range of display & measurement options: Pulse-Echo, Echo-Echo, Pulse-Echo Temp, Comp Mode (PETP), Coating Only Mode (CT), Pulse-Echo Coating Mode (PECT)

- Manual or automatic gain control (AGC) with adjustable 110dB range

- Gate control

- Threshold adjustment

- 64 User defined setups

- Multiple language display

- Multiple calibration and material selection options

- High speed scan mode: 250 readings per second (Dakota CMX1 Ultrasonic Thickness Gauge and Dakota CMX1-DL Ultrasonic Thickness Gauge), 50 readings per second (Dakota CMX2-DL Ultrasonic Thickness Gauge and Dakota CMX3-DL Ultrasonic Thickness Gauge)

- A-Scan portrait & landscape views (Dakota CMX3-DL Ultrasonic Thickness Gauge only)

- Differential and minimal thickness alarm modes

- Data output and storage: 4GB internal memory

- Download to DakMaster™ data management software

Key Features

Repeatability / Stability Indicator

Consisting of 6 vertical bars, when all the bars are fully illuminated and the last digit on the digital thickness value is stable, the gauge is reliably measuring the material thickness.

High Speed Scan with Minimum Thickness Display

By significantly increasing the measurement refresh rate this mode allows the user to make scanned passes over the test material. The smallest thickness value is held in memory and displayed when scanning is complete. This feature can also be used in conjunction with the minimum & maximum limit alarm feature (model dependant).

Differential Mode

Once a user defined nominal thickness value has been set, the gauge will display the +/- thickness difference from the nominal value entered.

Limit Alarm Mode

The user can define minimum and maximum thickness limits. If the measurement falls outside the upper or lower limit a red LED will light and the beeper sounds. A green LED will light to indicate an acceptable thickness.

V-Path Correction

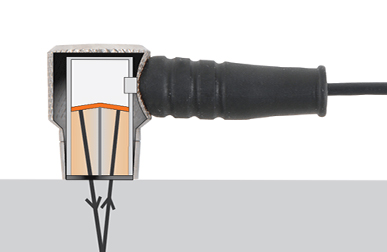

Dual element transducers consist of a probe with two crystals (one to transmit and one to receive the sound pulse). The crystals are separated by an acoustic barrier – generating a ‘V-shaped’ sound path as the sound travels from one element to the other. This path is slightly longer than the direct path therefore V-path correction is used to calculate the correct thickness

Measurement Modes

Measurement Modes Explained

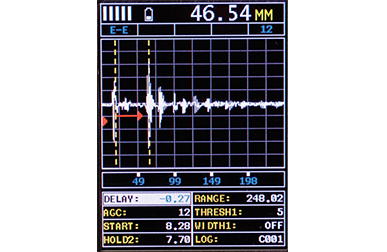

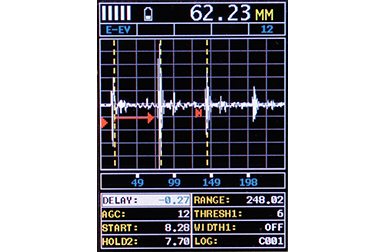

Pulse – Echo Mode (PE):

The normal display mode, measures the total thickness from the base of the transducer probe to the material density boundary (typically the back wall). Ideal for pit and flaw detection.

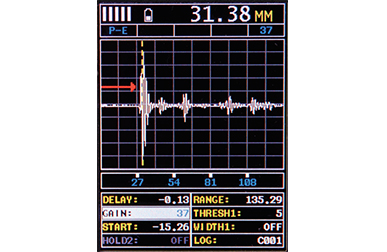

Echo – Echo Mode (EE):

Also known as the ThruPaint™ Mode, EE ignores the coating thickness, displaying the material thickness from the top surface of the material to the material density boundary.

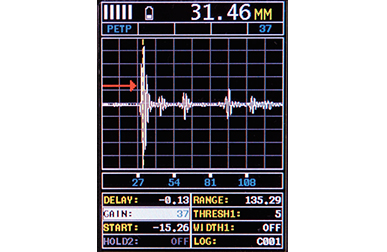

Pulse – Echo Temp Comp Mode (PETP):

Similar to the PE mode, PETP takes into account and compensates for the variations in measurement caused by temperature variations.

Echo – Echo Verify Mode (EEV):

The echo-echo verify mode measures by comparing the values between 3 reflections and is commonly used to eliminate errors from surface coatings and to make measurements in multiple layered materials.

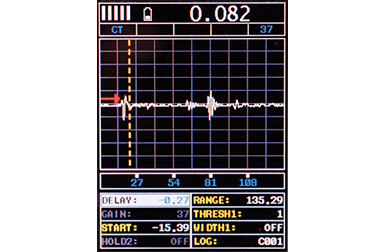

Coating Only Mode (CT):

Displays the thickness of the coating applied to the material.

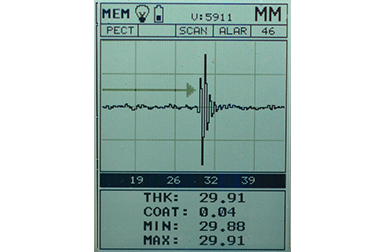

Pulse – Echo Coating Mode (PECT):

Displays both the material thickness (PE) and the coating thickness (CT) at the same time.

Basic Flaw Mode (FLAW MODE):

Basic prove-up flaw detection using single element angle beam transducers is available on the CMX2-DL and CMX3-DL corrosion thickness gauges.

Display Modes Explained

Material Thickness Digits Display:

The standard display on all models, this displays the numerical thickness value in either millimetres (MM)or inches (IN).

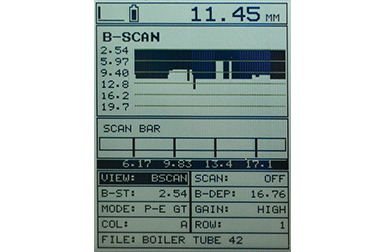

Scan Bar Display:

A linear graphic display which allows users to graphically monitor changes in thickness readings. As the scale range can be adjusted by the user, this display is ideal for observing tiny variations in material thicknesses.

B-Scan Display:

A time based cross sectional 2D block view of the thickness provides a graphical view of the material thickness – ideal for relative depth analysis.

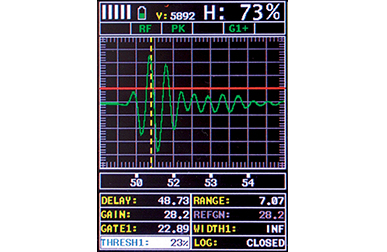

| A-Scan Display; Full Wave (RF):*

The A-Scan display shows the sine wave created by the reflected sound, or oscillation, from the material being measured. In RF mode the full wave form is displayed. A-Scan Display; Rectified (+ or -):* Users can select to view either the positive or the negative cycle of the full waveform (RF). This rectified (RECT) display shows the amplitude of the echo versus the transit time. * Available on CMX2-DL and CMX3-DL thickness gauge Models only |

Product Features

Product Features

| Model | CMX1 | CMX1-DL | CMX2-DL | CMX3-DL |

| Display Mode | ||||

| Material thickness digits display |

■ |

■ |

■ |

■ |

| B-Scan cross sectional display |

■ |

■ |

■ |

■ |

| Combined B-Scan and digits display |

■ |

■ |

■ |

■ |

| Coating Thickness Display |

■ |

■ |

■ |

■ |

| Scan Bar Display | ||||

| A-Scan Display | + Rectified, – Rectified, Full Waveform (RF) Portrait & landscape views | |||

| Measurement Range | PE: 0.63 – 1219.2mmPETP: 0.63 – 1219.2mm

EE: 2.54 – 152.4mm EEV: 1.27 – 25.4mm CT: 0.01 – 2.54mm PECT: 0.63 – 1219.2mm PECT: 0.01 – 2.54mm |

PE: 0.63 – 1219.2mmPETP: 0.63 – 1219.2mm

EE: 2.54 – 152.4mm EEV: 1.27 – 25.4mm CT: 0.01 – 2.54mm PECT: 0.63 – 1219.2mm PECT: 0.01 – 2.54mm |

PE: 0.63 – 1219.2mm

PETP: 0.63 – 1219.2mm EE: 2.54 – 152.4mm EEV: 1.27 – 25.4mm CT: 0.01 – 2.54mm PECT: 0.63 – 1219.2mm PECT: 0.01 – 2.54mm |

PE: 0.63 – 1219.2mm

PETP: 0.63 – 1219.2mm EE: 2.54 – 152.4mm EEV: 1.27 – 25.4mm CT: 0.01 – 2.54mm PECT: 0.63 – 1219.2mm PECT: 0.01 – 2.54mm |

| Measurement Rate | ||||

| Manual | 8 readings per second | 8 readings per second | 8 readings per second | 8 readings per second |

| Scan Mode | 250 readings per second | 250 readings per second | 50 readings per second | 50 readings per second |

| Scan bar display | 10 readings per second | 10 readings per second | 10 readings per second | 10 readings per second |

| Measurement Resolution | 0.01mm | 0.01mm | 0.01mm, 0.001mm selectable | 0.01mm, 0.001mm selectable |

| Velocity Calibration Range | 309.88 – 18,542m/s | 309.88 – 18,542m/s | 309.88 – 18,542m/s | 309.88 – 18,542m/s |

| Additional Features | ||||

| High Speed Scan Mode |

■ |

|||

| Differential Mode |

■ |

|||

| Limit alarm mode |

■ |

|||

| B-Scan Display Speed | 15 readings per second | 15 readings per second | 15 readings per second | 10 to 200 readings per second |

| Flaw Mode | Basic prove-up flaw detection using single element angle beam transducers | Basic prove-up flaw detection using single element angle beam transducers | ||

| Calibration Setups | 64 user-definable setups transferable to and from a PC archive | |||

| Gates | 3 fully adjustable gates: start, stop, width & threshold | 3 fully adjustable gates: start, stop, width & threshold | ||

| Damping | Adjustable damping (50 – 1500ohms) | Adjustable damping (50 – 1500ohms) | ||

| Pulser Type | Dual square wave pulsers Pulse repetition frequency up to 250Hz |

Dual square wave pulsers Pulse repetition frequency up to 250Hz |

Dual square wave pulsers Pulse repetition frequency up to 250Hz |

Dual square wave pulsers Pulse repetition frequency up to 250Hz |

| Gain | Manual or automatic gain control (AGC) with 110dB range (limited) | Manual or automatic gain control (AGC) with 110dB range (limited) | Manual, automatic gain control (AGC) with 110dB range (limited), Linear time dependent gain (TDG) with adjustable slope | Manual, automatic gain control (AGC) with 110dB range (limited), Linear time dependent gain (TDG) with adjustable slope |

| Timing | Precision temperature controlled crystal oscillator (TCXO) timing with single shot 100MHz 8bit ultra-low power digitizer | Precision temperature controlled crystal oscillator (TCXO) timing with single shot 100MHz 8bit ultra-low power digitizer | Precision temperature controlled crystal oscillator (TCXO) timing with single shot 100MHz 8bit ultra-low power digitizer | Precision temperature controlled crystal oscillator (TCXO) timing with single shot 100MHz 8bit ultra-low power digitizer |

| Memory and Data Logging | • 4GB internal memory • Sequential and grid logging • Alpha numeric batch identification • OBSTRUCT indicates inaccessible locations • Bitmap graphic capture and capture viewer |

• 4GB internal memory • Sequential and grid logging • Alpha numeric batch identification • OBSTRUCT indicates inaccessible locations • Bitmap graphic capture and capture viewer |

• 4GB internal memory • Sequential and grid logging • Alpha numeric batch identification • OBSTRUCT indicates inaccessible locations • Bitmap graphic capture and capture viewer |

• 4GB internal memory • Sequential and grid logging • Alpha numeric batch identification • OBSTRUCT indicates inaccessible locations • Bitmap graphic capture and capture viewer |

| Calibration Options | ||||

| 1 – point |

■ |

■ |

■ |

■ |

| 2 – point |

■ |

■ |

■ |

■ |

| Material selection |

■ |

■ |

■ |

■ |

| Velocity (speed of sound) |

■ |

■ |

■ |

■ |

| Transducer Probe Type | Dual element | Dual element | Dual element | Dual Element, Single Element (1 – 20Mhz), Contact, Matching Layer, Delay Line and Pencil |

| Transducer Frequency Range | 1 – 10MHz | 1 – 10MHz | 1 – 10MHz | 1 – 20MHz |

| Transducer Recognition | Automatic & manual – selectable from a list | Automatic & manual – selectable from a list | Automatic & manual – selectable from a list | Automatic & manual – selectable from a list |

| V-path / dual path error correction | Automatic | Automatic | Automatic | Automatic |

| Probe Zero | Automatic & manual (via integrated probe disk) | Automatic & manual (via integrated probe disk) | Automatic & manual (via integrated probe disk) | Automatic & manual (via integrated probe disk) |

| Display | 1/8 VGA (greyscale) 62 x 45.7mm viewable area |

1/8 VGA (greyscale) 62 x 45.7mm viewable area |

1/8 VGA (greyscale) 62 x 45.7mm viewable area |

1/4 VGA AMOLED colour display 57.6 x 43.2mm viewable area Landscape Mode |

| Display Refresh Rate | 25Hz | 25Hz | 25Hz | 120Hz |

| Units (selectable) | mm or inches | mm or inches | mm or inches | mm or inches |

| LED Backlight | on/off/auto | on/off/auto | on/off/auto | adjustable brightness |

| Repeatability / Stability Indicator |

■ |

■ |

■ |

■ |

| Battery Save Mode | Auto | Auto | Auto | Auto |

1 Measuring range & accuracy depends on material, surface conditions and the transducer selected

Specifications

Dakota CMX Corrosion Thickness Gauges – Specifications

| Part Number | Description | Certificate |

| Z-170-0005 | Dakota CMX1 Thickness Gauge (CMX) |  |

| Z-171-0005 | Dakota CMX1-DL Thickness Gauge (CMX-DL) |  |

| Z-172-0005 | Dakota CMX2-DL Thickness Gauge (CMX-DL+) |  |

| Z-187-0005 | Dakota CMX3-DL Thickness Gauge (CMX-DL+ Colour) |  |

| Transducer Probe Type | Dual Element | |

| Measurement Accuracy1 | 0.01mm | |

| Memory | 4GB Internal Memory | |

| Operating Temperature | -10 to 60ºC | |

| Data Output | USB | |

| Power Supply | 3 x AA batteries and via USB | |

| Battery Life | Alkaline: greyscale 35 hrs, colour 12 hrs, Nicad: greyscale 10 hrs, colour 5 hrs, NI-MH: greyscale 35 hrs, colour 12 hrs | |

| Gauge Weight | 383g – including batteries | |

| Gauge Dimensions | 63.5 x 165 x 31.5mm | |

| Packing List | Unit, Selectable Transducer, Couplant, Manual, Plastic Carrying Case, Certificate of Calibration and AA Batteries. PC Software and Data Transfer Cable included with data logging gauges. | |

1Measuring range & accuracy depends on material, surface conditions and the transducer selected

2Approximate battery life, when in continuous measurement mode.

● Certificate of Calibration supplied as standard.

Packing list

| Selectable Dakota CMX Unit |

| Selectable Transducer |

| Couplant |

| Manual |

| Plastic Carrying Case |

| Certificate of Calibration |

| AA Batteries |

| PC Software and Data Transfer Cable included with data logging gauges. |

Data Sheet

Standards

Factory calibration traceable to NIST & MIL-STD-45662

Part Numbers

|

Dakota CMX1 Corrosion Thickness Gauge |

| Part Number : Z-170-0005 | |

|

Dakota CMX1-DL Corrosion Thickness Gauge |

| Part Number : Z-171-0005 | |

|

Dakota CMX2-DL Corrosion Thickness Gauge |

| Part Number : Z-172-0005 | |

|

Dakota CMX3-DL Corrosion Thickness Gauge |

| Part Number : Z-187-0005 |