Elcometer 2050 High Precision Grindometer

Product Description

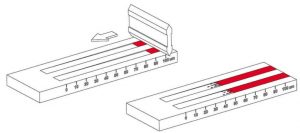

| This single channel precision grind gauge is used to determine particle size and fineness of grind for many materialsincluding paints, pigments, inks, coatings, chocolates, and other similar products.

Manufactured out of hardened stainless steel, each gauge is graduated in microns on the top to an accuracy of ±3μm or ±5% whichever is the greater. The groove width is 12mm and the groove length is 200mm. The High Precision Grindometer has a single groove. |

|

The Elcometer 2050 High Precision Grindometer can be used in accordance with:

• ASTM D 1210

• AS/NZS 1580.204.1

• DIN 53203*

• EN 21524*

• FTMS 141 4411.1

• ISO 1524

• JIS K 5600-2-5

• NF T30-046*

* Standards not in bold have been superseded but are still recognised in some industries

Specifications

| Part Number | Model | Range µm | Graduation µm | Certificate |

| K0002050M001 | Elcometer 2050/1 | 0-25 | 1 | ο |

| K0002050M002 | Elcometer 2050/2 | 0-50 | 2 | ο |

| K0002050M005 | Elcometer 2050/5 | 0-100 | 5 | ο |

| K0002050M008 | Elcometer 2050/8 | 0-250 | 12.5 | ο |

| Accuracy | ±3µm or ±5% whichever is the greater | |||

| Packed Dimensions | 312 x 270 x 79mm | |||

| Packed Weight | 1.75kg | |||

ο Optional Calibration Certificate available

Packing List

- Elcometer 2050 High Precision Grindometer

- Scraper

- Transit Case

- Operating Instructions

Data Sheet

Standards

The Elcometer 2050 High Precision Grindometer can be used in accordance with:

• ASTM D 1210

• AS/NZS 1580.204.1

• DIN 53203*

• EN 21524*

• FTMS 141 4411.1

• ISO 1524

• JIS K 5600-2-5

• NF T30-046*

* Standards not in bold have been superseded but are still recognised in some industries

Accessories

| Part Number | Description |

| KT002030N001 | Replacement Scraper for Elcometer 2050 |

Instruction Manual

Video

To measure the dispersion (or measure the particle size) of a material, a fineness of grind gauge, also known as a grindometer, is used.

Contents

0:49 Elcometer’s Fineness of Grind gauges

2:16 How to complete a test

3:41 How to read the result

Elcometer precision manufacture and supply three different types of fineness of grind gauges, or grindometers.

Dual channel gauges, such as the Elcometer 2020, which are available in various scale ranges, and are ideal for testing the dispersion of many materials including paints, coatings, cosmetics, chocolates, and other similar products.

The Elcometer 2020 gauges are available with either mil or micron scales; and include two other scales as standard – the PCU (North) scale where your material is compared with a known sample, and the NS (Hegman) scale which reports the distance from the deepest end of the channel.

Dual channel gauges also allow you to test different material formulations side-by-side, so you can instantly compare the results.

Alternatively there are high precision single channel grindometers, such as the Elcometer 2050, available in either mils or microns. The combination of the same depth, that’s precision ground across a longer channel, means the Elcometer 2050 allows you to measure to a greater accuracy, of ±1μm (±0.04mil).

And the NPIRI Fineness of Grind gauge, the Elcometer 2070, precision made for determining dispersion in printing inks according to the National Printing Inks Research Institute scale, as well as either mils or microns.

This video will guide you through how to measure dispersion using a grindometer / fineness of grind gauge / Hegman gauge.