Home » Products » Coating Inspection » Coating Thickness Gauges » Dry Film Coating Thickness Gauge – Digital » Elcometer 456 IPC Industrial Protective Coating Thickness Gauge

Elcometer 456 IPC Industrial Protective Coating Thickness Gauge

Product Description

The Elcometer 456 Industrial Protective Coating Thickness Gauge is designed to measure dry film thickness on shot or grit blasted steel substrates.

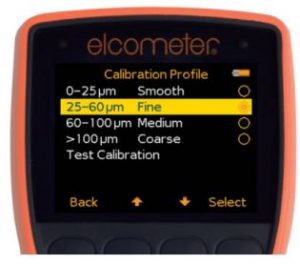

Pre-calibrated with 4 profile ranges to ensure accurate coating thickness measurement on blasted substrates, the Elcometer 456 IPC Thickness Gauge is fast and very easy to use.

Profile Ranges

The user selectable surface profiles include smooth, fine, medium and coarse ranges. The gauge’s built-in integral ferrous probe allows thickness measurements to be taken on flat or curved surfaces, in mils or microns.

| Profile | Metric |  |

| Smooth | 0-25μm | |

| Fine | 25-60μm | |

| Medium | 60-100μm | |

| Coarse | >100μm |

With a reading rate of 70+ readings per minute, the gauge displays three individual thickness readings together with the average. Coating thickness readings can be transferred via Bluetooth® or USB to ElcoMaster®, or your own software application, for instant report generation.

Features of the Elcometer 456 IPC Dry Film Thickness Gauge

- Pre-calibrated with 4 profile ranges

- Displays 3 individual readings together with their average in microns

- Stores up to 150,000 readings in 2,500 batches

- Built in integral probe for stable, repeatable readings on flat or curved surfaces

- USB or Bluetooth® data output to the ElcoMaster® or your own software application

The Elcometer 456 IPC Dry Film Thickness Gauge can be used in accordance with:

- ASTM D7091,

- ISO 2808,

- ISO 19840,

- SSPC PA-2,

- US Navy NSI 009-32

Specifications

| Model | Model S | Model T |

| Part Number | A456CFI1-IPC | A456CFTI1-IPC |

| Test Certificate | • | • |

| Fast, accurate reading rate; 70+ readings per minute | ■ | ■ |

| Data output | ■ | ■ |

| USB; to computer | ■ | ■ |

| Bluetooth®; to computer, Android™ & iOS1 devices | ■ | ■ |

| On screen statistics; in Batch Mode | ■ | ■ |

| Number of readings; η, Mean (average); x, Standard deviation; σ, Highest reading; Hi, Lowest reading; Lo, Coefficient of variation; CV%, Elcometer index value2; EIV, Nominal dry film thickness; NDFT, High & low limits; definable audible & visual alarms, Number of readings above high limit; Number of readings below low limit | ■ | |

| ElcoMaster® software & USB cable | ■ | |

| Integral Probe type; Ferrous (F) | ■ | ■ |

| Measurement range; 0 – 1,500μm | ■ | ■ |

| Resolution; 10μm (where 5μm is rounded up) | ■ | ■ |

| Accuracy3; ±5% | ■ | ■ |

| Minimum substrate thickness; 300μm | ■ | ■ |

| Pre-calibrated with 4 profile ranges5; | ■ | ■ |

| Smooth 0-25µm, Fine 25-60µm | ■ | ■ |

| Medium 60-100µm, Coarse >100µm | ||

| Auto calibration | ■ | ■ |

| Calibration memory type; gauge (g) or gauge & batch (gb) | g | gb |

| Number of batches with unique calibrations | 2 500 | |

| Calibration lock with optional PIN code unlock | ■ | ■ |

| Delete last reading | ■ | ■ |

| Gauge memory number of readings | 150 000 | |

| Individual batch calibrations; sent to PC via ElcoMaster® software | ■ | |

| Limits; user definable audible & visual pass/fail warnings | ■ | |

| Gauge & batch specific limits | ■ | |

| Date and time stamp | ■ | |

| Review, clear & delete batches | ■ | |

| Batch types; normal, counted average | ■ | |

| Batch review graph | ■ | |

| Copy batches and calibration settings | ■ | |

| Alpha-numeric batch names; user definable on the gauge | ■ | |

| Operating Temperature | -10 to 50°C | |

| Battery Type | 2 x AA batteries, rechargeable batteries can also be used | |

| Battery Life4 | Alkaline: Approx. 16 hours | |

| Lithium: Approx. 24 hours | ||

| Weight (including batteries) | 156g | |

| Gauge Dimensions | 141 x 73 x 37mm | |

2 Elcometer Index Values are used in the automotive industry to assess a coating’s overall quality; USA patent number US7606671B2

3 When in test calibration mode

4 Using default settings & lithium batteries, alkaline or rechargeable batteries may differ

5 European Patent Number: 2754993

Packing List

- Elcometer 456 IPC Gauge

- Calibration foils

- Wrist harness

- Protective case

- 1 x screen protector

- USB cable

- Test certificate

- 2 x AA batteries & user guide

Data Sheet

Instruction Manual

Standards

The Elcometer 456 IPC Dry Film Thickness Gauge can be used in accordance with:

- ASTM D7091,

- ISO 2808,

- ISO 19840,

- SSPC PA-2,

- US Navy NSI 009-32

Video

The Elcometer 456 Industrial Protective Coating Thickness Gauge is a fast and easy to use DFT gauge designed to measure dry film thickness on shot or grit blasted steel substrates.

Pre-calibrated with 4 profile ranges to ensure accurate coating thickness measurement on blasted substrates, the Elcometer 456 IPC Thickness Gauge can take over 70 readings per minute – significantly reducing inspection times.

A recent study by the National Shipbuilding Research Program researched the use of digital inspection tools in accordance with 009-32. The NSRP found that by using a pre-calibrated Elcometer 456 they were able to measure dry film thickness in half the time of of their current DFT measurement methods.

Coating thickness readings can be transferred via Bluetooth® or USB to ElcoMaster®, or your own software application, for instant report generation.